MMM, Iron!

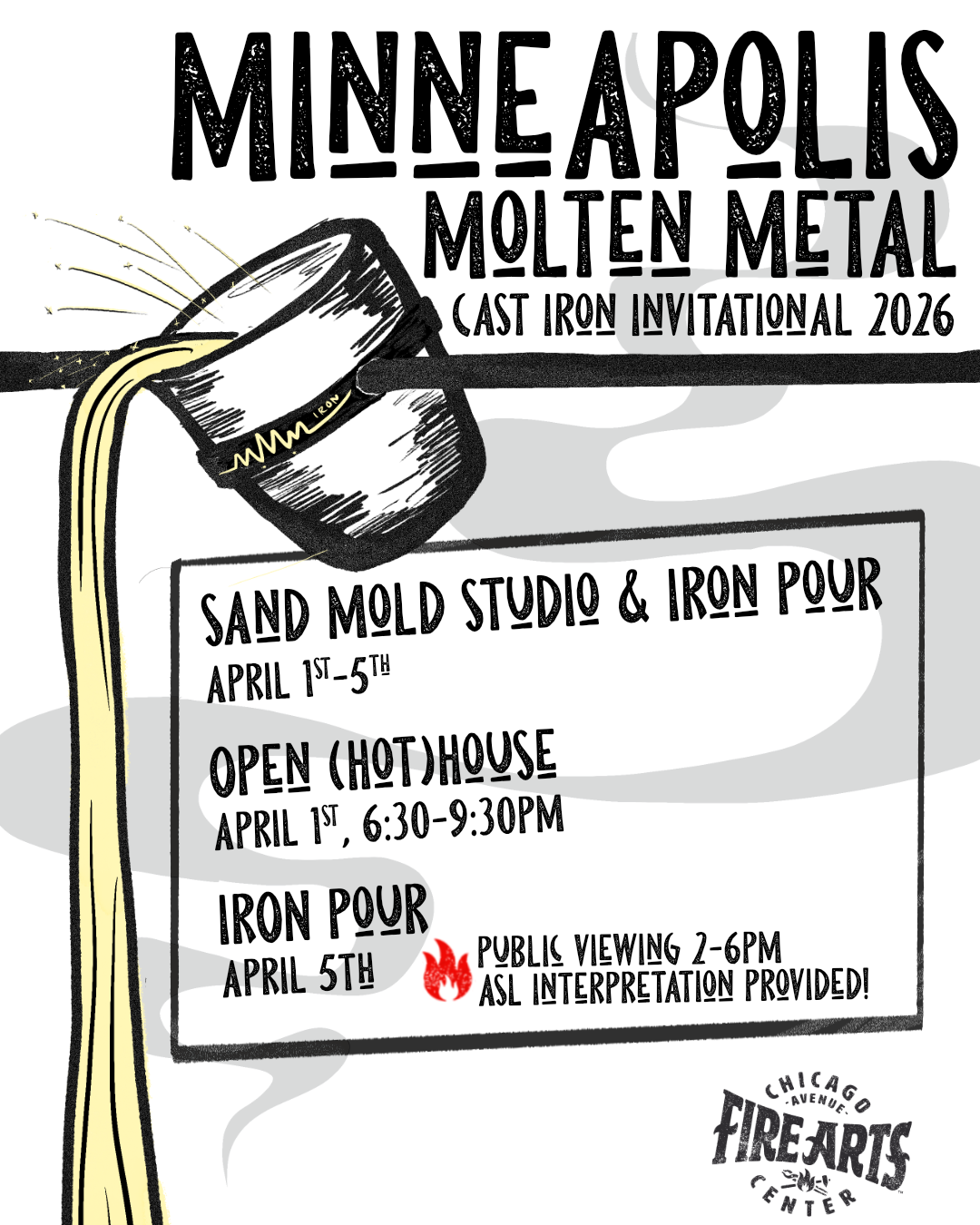

The 2026 Minneapolis Molten Metal Cast Iron Invitational

It’s back! This April, the Chicago Avenue Fire Arts Center is proud to host the second annual Minneapolis Molten Metal Cast Iron Invitational, a five‑day, neighborhood‑scaled iron‑casting festival that transforms CAFAC into an open, collaborative foundry. By pairing hands-on workshops with a public iron pour, the Minneapolis Molten Metal demystifies an art form that is usually hidden behind industrial walls and invites residents, artists, and visitors to co‑create awe‑inspiring artworks with molten metal.

We’re hosting a series of iron workshops and events, including one-day scratch tile workshops and — the main event — a four-day intensive sand mold studio culminating in a community iron pour on April 4th!

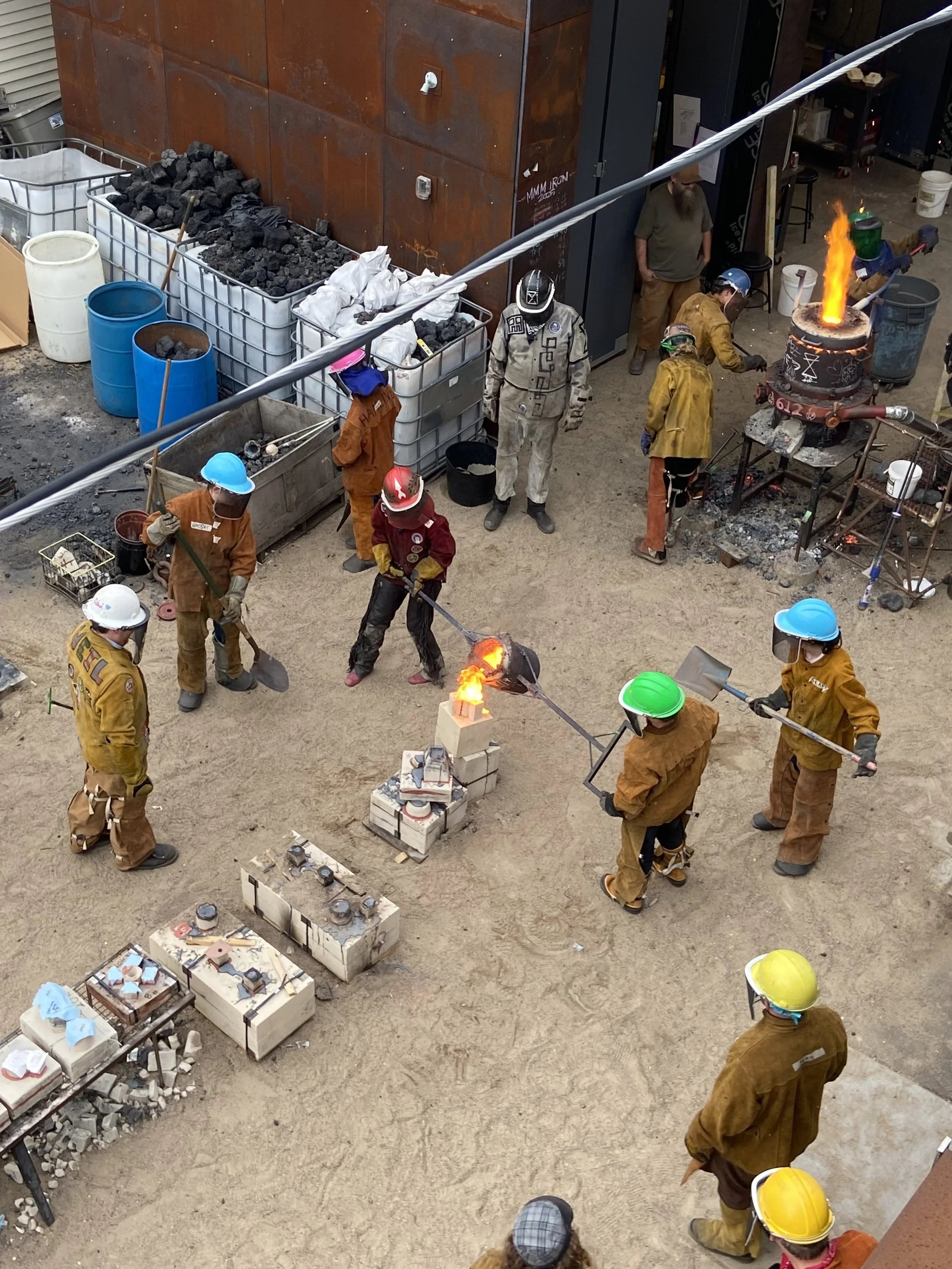

This iron pour is an annual event open to the whole community, turning a once‑exclusive craft into a vibrant neighborhood ritual one that melts metal and the boundaries between artist, neighbor, and visitor.

Join us! Public viewing of the pour from 2 to 6pm on Saturday, April 4th. Hosted by an MC, with ASL interpretation provided.

Questions on the event, including accessibility considerations? Email us at info@cafac.org.

MMM Iron 2026 Workshops

Cast Iron Workshop:

Sand Mold Studio

Wednesday - Sunday, April 1 - 5

See full schedule

This four-day immersive workshop will culminate in community iron pour on Saturday, April 4. Open to artists and students of all skill levels, this sand mold workshop offers hands-on experience in casting molten iron using traditional foundry techniques. Whether you're a beginner or an experienced caster, you'll learn new skills, connect with fellow makers, and create a custom iron casting.

Materials included in the Sand Studio Workshop

During the workshop, instructors will assist in establishing parting lines and ramming multi-part molds using resin-bonded sand. You’re encouraged to bring a completed pattern or object robust enough to withstand the ramming process. You can create between one to three molds with no more than six parts per mold.

The workshop includes 30 pounds of iron and 100 pounds of resin-bonded sand, including gating systems. 100 pounds of sand typically is enough to make 1-4 castings, depending on size. If you need additional materials, you can purchase from CAFAC at the following rates:

$1 per lb of resin-bonded sand

$1 per lb of iron

Because of our urban setting we do not allow reaction molds, foam burn outs, or any type of mold that will create black smoke or start a fire.

Casting Project Shop:

Make a Cast Iron Art Tile

Saturday, March 21

10 a.m. to 1 p.m.

In this workshop, you’ll create a sand mold of your own design to be cast in iron at the Minneapolis Molten Metal Cast Iron Invitational. We’ll discuss the basics of the iron casting process and guide you through the process of reductive carving to create the mold for your tile. The workshop will ignite your interest in one of the myriad methods of metal casting and the magic of molten metal! No prior experience required.

MMM Iron:

Community Scratch Tile Workshop

Saturday, April 4

10 a.m. to 1 p.m.

This one’s for you, Minneapolis. In this workshop, you’ll create a sand mold of your own design to be cast in iron at the Minneapolis Molten Metal Cast Iron Invitational. We’ll discuss the basics of the iron casting process and guide you through the process of reductive carving to create the mold for your tile. The workshop will ignite your interest in one of the myriad methods of metal casting and the magic of molten metal! No prior experience required. Free for Minneapolis residents, in honor of your strength, courage, and beauty.

Bring Your Own Mold /

Pour Crew Signup

If you plan to pour with us or bring a mold please sign up by April 1. Sign-up link coming soon!

Breaking Iron: All iron must be broken by 12pm on Saturday, April 4, before the pour. You are welcome to break iron on April 1, 2, 3 or 4, anytime after 10am.

Mold Drop Off: All molds must be on site by 12pm on Saturday, April 4 and you should include your iron estimates in the sign up sheet.

Mold Types Supported: Sand molds or clay molds are great! We will NOT have access to a melt out kiln so all molds should be ready to pour. We will have a speedy melt furnace onsite used to preheat ceramic shell. Ceramic shell molds should be melted out, vitrified and patched when you arrive. We will have limited availability in our preheat. Please email Brighton McCormick with ceramic shell questions.

Pour Crew Sign Up: Be sure your name is on this list if you’d like to pour metal. We prioritize folks that bring molds - make something, get skin in the game!

Purchasing Iron: We will weigh your casting on Sunday after the pour and only charge you for what you actually use. This includes your gating system. Iron is $1 per lb.

Because of our urban setting we do not allow reaction molds, foam burn outs, or any type of mold that will create black smoke or start a concerning fire.

For pattern suitability questions, contact Brighton McCormick: brighton.mccormick@gmail.com

Facilities, Equipment, and Supplies

All workshops and the pour will be at Chicago Ave Fire Arts Center in our full equipment foundry and metal shop.

We provide:

Sand mixer with a 100-pound capacity. We use 3050 mesh silica sand.

Sodium silicate self setting resin/catalyst system from United Erie, with a 4-hour set time (plan for less than 6 part molds)

Flasks, bottom boards, and sand mixing tools (if you have a very particular pattern we encourage you to bring flasks or bottom boards). We do not have a woodshop onsite.

Our cupolette (aka Calcifer) is limited to 75-pound taps. We do not recommend molds requiring more than 50 pounds of iron.

Complete foundry leathers in a variety of sizes.

Access to angle grinders and hand tools.

Pattern materials:

Swage Block (limited patterns available, email us immediately to reserve use)

Belt Buckle Positive: that can utilize wax or plasticine to make a custom buckle

Bowl Positive: that can utilize wax or plasticine OR reductive carving methods to make a custom bowl

Recommended items for students to bring (if available):

Pattern or object to mold

Personal PPE: gloves, safety glasses, face shield, hearing protection, cotton clothing, long sleeve shirt, work boots, foundry leathers

Any personal mold making tools (CAFAC will have all essential tools)

Schedule

Subject to change based on group dynamics and the will of the iron gods.

Wednesday, April 1

10am - 11am: Welcome to CAFAC and orientation

11am - 12pm: Pattern inspection and preparation, assign work stations

Noon - 1pm: Lunch (bring your own or visit local restaurant recommendations)

1pm - 1:15pm: Iron breaking setup (you can break iron anytime during work time)

1:15pm - 1:45pm: Cupolette Lecture with Iron Breaking Demo

1pm - 2pm: Gating basics, flask preparation and assembly

2pm - 6pm: Work time, part lines and sand mixing. Ram first part of molds.

6:30pm - 9pm: Open (Hot)House

Join us for fiery festivities at CAFAC’s semi-annual community event! Featuring demos, a gallery exhibit, snacks and refreshments, music, and fire performance. Fun for all ages, open to anyone with an interest!

Thursday, April 2

10am - 12pm: multi-part mold-making demos and work time, iron breaking

Noon - 1pm: Lunch (bring your own or visit local restaurant recommendations)

1pm - 6pm: multi-part mold making demos and work time, iron breaking

TBD: After party and hangs at near by bars and houses

Friday, April 3

10am - 12pm: Gating and venting

Noon - 1pm: Lunch (bring your own or visit local restaurant recommendations)

1pm - 2pm: Gluing, banding and weighting demos

2pm - 6pm: Multi-part mold-making demos and work time, iron breaking

All molds must be finished by 8pm

TBD: After party and hangs at near by bars and houses

Saturday, April 4

10am - 12pm: Pour floor setup

12pm - 12:30pm: Lunch (bring your own or visit local restaurant recommendations)

12:30pm - 2pm: Assign pour teams, dry run, organize charges

1pm: Safety talk

12pm: Burn in

Between 2pm - 3pm: First tap! Pour until we’re done, followed by cleanup

Public Viewing Hours 2pm - 6pm with MC & ASL Interruption

BBQ & After Party for students, artists & pour team to follow (provided by CAFAC)

Sunday, April 5

10am - 12pm: Clean up, break open mold, weigh and pay for iron

12pm - 2pm: Brunch (optional at local restaurant)

2pm - 4pm: Final clean up/pack up equipment

Meet the team

Pete Gierzynski (he/him)

Pete is a local artist and blacksmith with a passion for DIY ethics and sharing knowledge to empower community. Pete runs his own metalworking business in south Minneapolis, where he crafts custom commissions.

Brighton McCormick (they/them)

Brighton is a sculptor, educator and art fabricator living and working in South Minneapolis. Their interdisciplinary practice focuses on sculpture and gallery installation, community engaged projects, and public art.

Jess Bergman Night (she/her)

Jess has been exploring art her entire life and was introduced to her first fire art form, cast metal, as a teenager. She has been teaching and creating with the cast metal professionally for the past decade.

Woody Stauffer (he/him)

Woody has been discovering and implementing methods of mold-making techniques primarily for the casting of metal and concrete for the past 10 plus years.